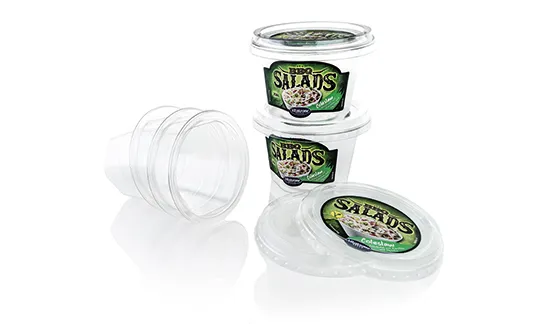

Thermoformed Round Container (In-Mould-Labelling)

BDT 001

Until now, In-Mould-Labelling technology has only been used for plastic injection-moulded packaging. Thanks to the innovative and efficient T-IML process, cups can be produced that are very light and have high-quality decoration at the same time.

High-quality decoration through in-mould labelling.

IML is an integral part of the packaging - moisture and temperature resistant and dishwasher safe.

Maximum material savings.

Compared to injection moulding, less plastic is used in thermoforming. Savings of > 25% are no exception.

Production-related savings of up to 30% for thermoformed cups and lids.

One cup cell and one lid magazine for all sizes.

As PP mono-packaging, all requirements of mechanical recycling are fulfilled: NIR detection, floating-sink process.

You may also be interested in these articles:

Whether flexible or rigid packaging:

Mono is a must!

The development of monomaterial packaging, i.e. single-material packaging, poses a particular challenge for packaging design in the packaging industry. For our monomaterial solutions, we make use of various implementation options:

- Injection molding with In-Mould-Labelling

- Thermoforming with In-Mould-Labelling

- LowSealing spouts for pouches