Material

We reduce the use of materials through resource-saving article concepts and efficient production processes.

Until now, In-Mould-Labelling technology has only been used for plastic injection-molded packaging. With the realization of a thermoformed dairy cup with IML, we combine our many years of experience in the areas of IML and thermoforming. The innovative and efficient T-IML process makes it possible to produce cups that are very light, as less plastic is used, and at the same time have a high-quality decoration.

IML is a captive component of the packaging - moisture and temperature resistant and dishwasher safe.

Compared to injection molding, less plastic is used in thermoforming. Cups are significantly lighter (savings of 25% are no exception).

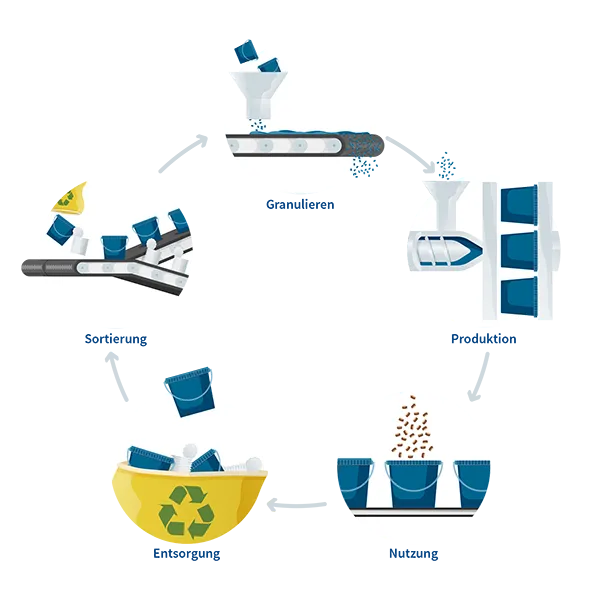

Maximum recyclability: cup and In-Mould-Label are made of the same material (polypropylene). This means that the cups are very easy to recycle as monomaterial packaging.

Our T-IML tubs are available in various sizes - so the right tubs are available for many applications in the dairy or delicatessen sector.

We reduce the use of materials through resource-saving article concepts and efficient production processes.

The use of recycled materials, high recyclability and environmentally friendly production conditions can maximize GHG reductions.

By optimizing the design of the item, stacking and nesting can be improved - maximizing the quantity per package unit and minimizing setup time on the production floor.

Optimized nesting allows for optimal use of existing capacity. The space required for internal and external logistics is reduced, resulting in cost savings.

The EU Packaging & Packaging Waste Regulation (PPWR) sets out the framework conditions for how packaging should be designed in the future. Unnecessary packaging and packaging waste should be reduced and reusable systems and recycling should be promoted. In our opinion, plastic packaging meets precisely these requirements, as plastic is more efficient than alternative materials.