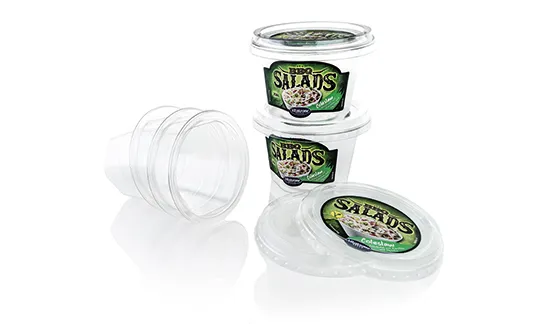

Round container

BD 003 & BD 008

Perfect for salads and fresh food.

Reduced material usage.

Due to the manufacturing process of the thermoformed cups and lids, thin wall thicknesses and thus weight savings of up to 30% compared to injection moulding can be achieved.

Highly recyclable.

As mono-packaging, all requirements of mechanical recycling are fulfilled: NIR detection, floating-sink process.

Production-related savings of up to 30% for thermoformed cups and lids.

PET and PP mono-packaging.

Decoration of the injection moulding cups and lids by using In-Mould-Labelling (IML).

You may also be interested in these articles:

Whether flexible or rigid packaging:

Mono is a must!

The development of monomaterial packaging, i.e. single-material packaging, poses a particular challenge for packaging design in the packaging industry. For our monomaterial solutions, we make use of various implementation options:

- Injection molding with In-Mould-Labelling

- Thermoforming with In-Mould-Labelling

- LowSealing spouts for pouches