laboratory &

Diagnostics

We develop and manufacture primary and secondary packaging for laboratory and molecular diagnostics with the highest precision and process reliability: GMP-compliant and certified according to DIN EN ISO 13485. Production takes place under fully automated cleanroom conditions in accordance with DIN EN ISO Class 7 / GMP Standard C. Whether PCR plates for in vitro diagnostics (IVD), spin columns for nucleic acid purification, or components for automated sample preparation—our solutions include hygiene, complete documentation, and reproducible quality for human and veterinary diagnostics.

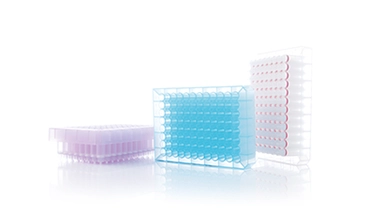

PCR and Filter plates

for IVD applications

Consumables

for molecular diagnostics & laboratory automation

Reagentbox

for secure sample storage and molecular analysis

Lab vessels

with and without lid for nucleic acid purification

Rack

stable holders for centrifuge columns

Spin Column

precisely manufactured columns for DNA/RNA isolation

Microtiter Plate

high-quality plates for reliable test series in the laboratory

Fully automated cleanroom production:

Less particle sources, even greater safety.

From prototype development to series production, we accompany your project as a reliable partner. Our experience covers laboratory vessels in all sizes—from mini to maxi, PCR plates, spin columns, and complete system solutions manufactured using injection molding. Assembly and packaging take place in a fully automated cleanroom in accordance with DIN EN ISO Class 7 and GMP Standard C, which means that hygienic conditions, maximum process reliability, and complete GMP-compliant documentation are our top priorities. This enables us to offer ideal conditions for applications in human and veterinary diagnostics, IVD products, and automated laboratory robotics systems.

Our Added Value,

Your Benefits.

STEFFEN

Your BENEFIT: Everything from a single source.

-

Development and manufacture of customized primary and secondary packaging for laboratories and diagnostics

-

Contract manufacturing including injection molding, packaging, and assembly

-

Fully automated production processes in cleanrooms (according to DIN EN ISO Class 7 / GMP Standard C)

-

Seamless quality management: GMP-compliant documentation certified according to DIN EN ISO 13485

-

In-house toolmaking for maximum flexibility

-

From concept to series production, everything from a single source – for maximum quality, efficiency, and regulatory compliance

-

We would be glad to present our advantages to you in a personal meeting.

continuous

quality assurance

Our packaging solutions for laboratory and molecular diagnostics meet the highest standards of quality, safety, and documentation. With DIN EN ISO 13485 certification, we enable compliance with the strictest GMP standards—from component development and design approval to delivery of the series product. We manufacture under DIN EN ISO Class 7 cleanroom conditions and GMP Standard C, and document process steps in accordance with Good Manufacturing Practice (GMP) rules. From the start of component development to the approval of the tool design, the highest demands are placed on technology and quality. In four qualification steps, the manufacturing process is checked and documented in detail across all phases of industrialization:

PÖPPELMANN FAMAC®.

Awarded and certified:

Systematic quality management for medical devices

International Sustainability &

Carbon Certification

Systematic

energy management

Systematic

environmental management

Management system

for health and safety