Our spouts and caps

Stand-up pouches replace existing packaging for pet and baby food, cleaning agents and detergents, body care and dairy products: easy handling, low weight and reduced waste volume. Our spouts impress with their high machine compatibility, the use of low-seal materials as the basis for monomaterial pouches and a range of different opening diameters - also in assembled versions if required.

Your benefits:

-

Patented corrugated sealing base that protects the film.

-

Solutions for any filling system: pouch and spout filling.

-

Different materials for recyclable monomaterial pouches.

-

Spouts for thermal and ultrasonic sealing.

-

Easy to open and reseal for maximum consumer convenience.

AE 001 SERIES

Diameter 10.5 mm

AE 002 SERIES

Diameter 12.5 mm

AE 003 SERIES

Diameter 17.5 mm

AE 004 SERIES

Diameter 21.5 mm

AE 005 SERIES

Diameter 8.5 mm

AE 007 SERIES

Diameter 8.5 mm

CUSTOMIZED SPOUTS

FUTURE-PROOF POUCHES

Minimal use of materials and maximum recyclability. We would be happy to discuss your application.

Innovations and challenges at Spouts.

In an episode of the Innoform podcast, Karsten Schröder welcomes Lea Middendorf and Mike Landwehr from Pöppelmann to talk about a key topic in flexible packaging: spouts. This component is an essential part of pouch packaging and plays an important role in handling and the consumer experience.

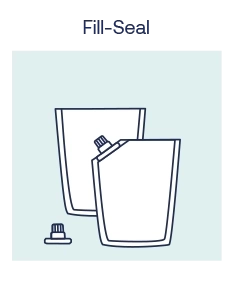

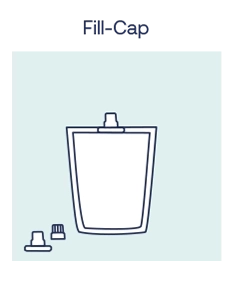

Spouts for all

filling systems.

Whether filling through the pouch (fill-seal) or filling through the spout (fill-cap), we have the solution for your application.

Scope of delivery

Filler receives pouches and pre-assembled spout with cap.

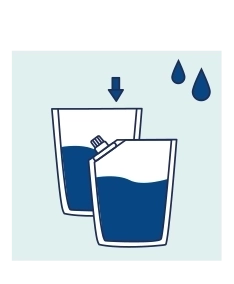

Filling

Filling through the top seam of the pouch.

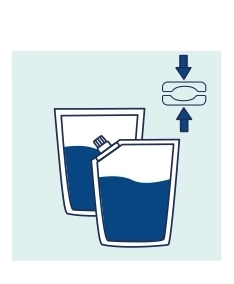

Capping

Weld the top seam of the pouch.

Scope of delivery

Filler receives pouches with inserted spouts.

Filling

Filling the pouches through the spout.

Capping

Close the spout with the separately supplied cap.

Recyclable spouts?

Why not!

Monomaterial pouches

- Spouts for thermal welding and ultrasonic welding (PP and PE).

- Material option "LowSealing".

- Screw caps with and without tamper-evidence in PP and PE.

Post-consumer-recyclate (PCR)

- PCR spouts and caps for the nonfood sector.

- Less GHG emissions through the use of PCR material.

- Available in PCR-PE and PCR-PP.

Test without obligation: reusable cups from the FAMAC® program.

Request samples of our packaging for testing - of course, completely free of charge and without obligation.

Fill out the form now and receive a sample range.