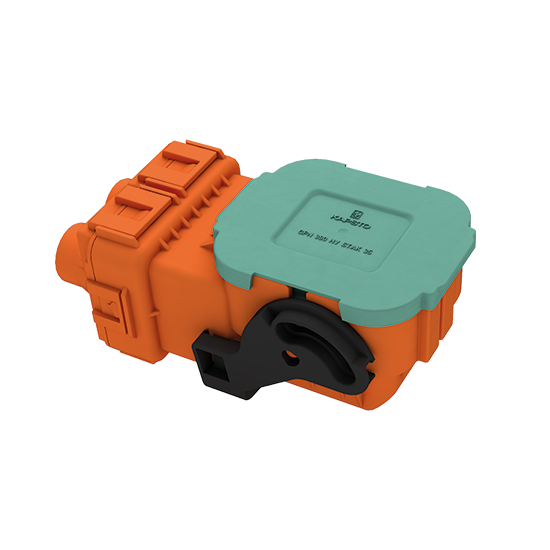

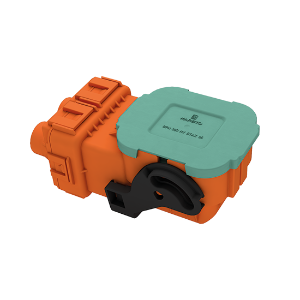

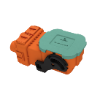

HV Connector Caps - GPN 390 Type A

The HV connector caps GPN 390 Form A is suitable for use on parts and components of hybrid or electric vehicles. It protects the plug connections, e.g. in the battery to inverter and electric motor area, against corrosion and mechanical damage and offers splash water protection in accordance with protection class IPX4. The plug has easy-grip side edges for quick removal and impresses with its functional design as a design pattern. The plastic used comes from post-consumer recycling.

- HV protection for external protection

- Production in accordance with ISO 16232 possible in a specially equipped clean room.

- The recyclate used is labelled with the Blue Angel.

This new series of standards is currently under development and will be available shortly. The information provided here is therefore provisional and subject to change. Our team will be happy to answer any questions you may have.

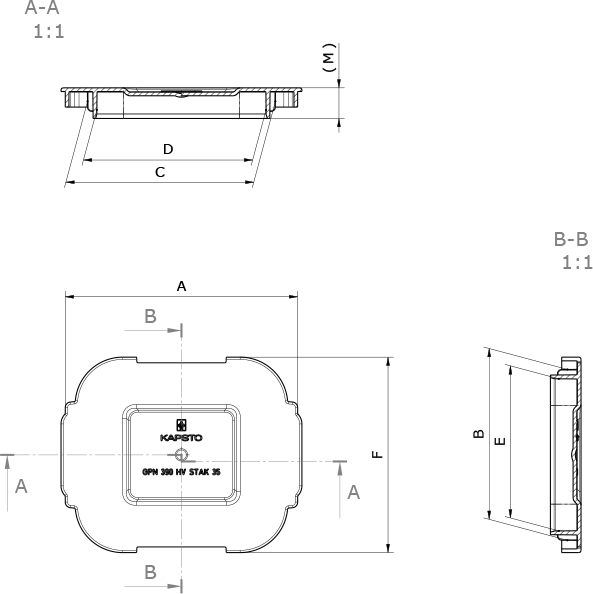

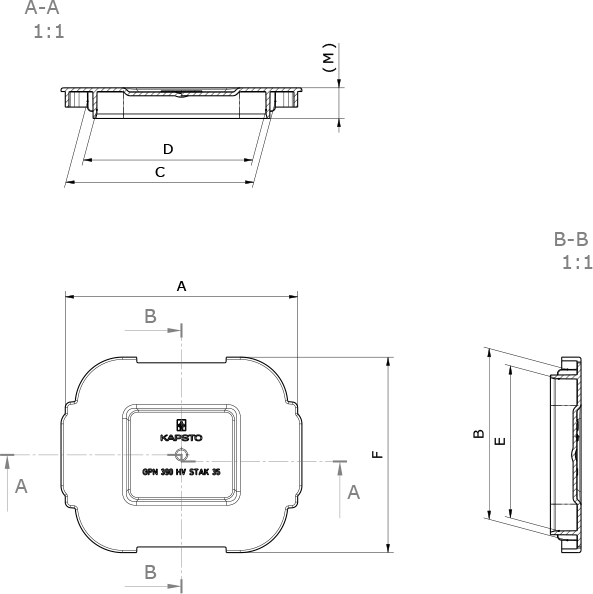

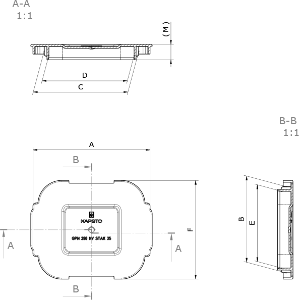

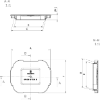

Dimensions

|

Dimensions

|

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Item

|

A

|

F

|

B

|

C

|

D

|

E

|

H

|

I

|

J

|

M

|

CAD

|

Order no.

|

|

| Available soon GPN 390 HV 0614 PCR-PP, turquoise blue | show | ||||||||||||

|

|

|||||||||||||

| Available soon GPN 390 HV 270-2 PCR-PP, turquoise blue | 47 | 63 | 44 | 49,2 | 8,7 | 44 | 49,2 | 11,1 | show | 39005010000 | |||

|

|

|||||||||||||

| Available soon GPN 390 HV STAK 35 PCR-PP, turquoise blue | 85 | 69 | 60,3 | 66,3 | 59,7 | 53,7 | 38 | 60,3 | 66,3 | 10,8 | show | 39006130000 | |

|

|

|||||||||||||

Dimensions in mm.

Information on materials, colours, designs and use of our products can be found on the website and in chapter 3´ Materials and application´.

Application guide

|

Item

|

Contact connections

|

||

|---|---|---|---|

| Available soon GPN 390 HV 0614 PCR-PP, turquoise blue | |||

| Available soon GPN 390 HV 270-2 PCR-PP, turquoise blue | HVR |

|

|

| Available soon GPN 390 HV STAK 35 PCR-PP, turquoise blue | HC-STAK |

|

|

The article consists of 98 % PCR-PP and 2 % colour based on a PIR carrier. The plastic used consists of 100 % PCR.

For these articles, colour deviations and black dots cannot be completely avoided in production and are permissible. We recommend carrying out functional tests before series production.

Quality advantages

More resource-saving.

Better fit.

Saves time.

Seals better.

Cleaner.

100% Post-Consumer Recyclate

100% Post-Consumer Recyclate