The future belongs to the circular economy. This is the consensus.

Our shared responsibility for our planet and future generations has given rise to fundamentally new economic principles in the 21st century. One of these principles is: the future belongs to the circular economy.

After all, the path to a true circular economy is one of the key strategic challenges both for our company and for the plastics industry as a whole. For this reason, we at Pöppelmann have been setting ourselves the task of shaping the shift from linear value creation to a circular economy for many years.

The end is always a new beginning: our blue cycle is based on nature’s green cycle.

What exactly is meant by circular economy?

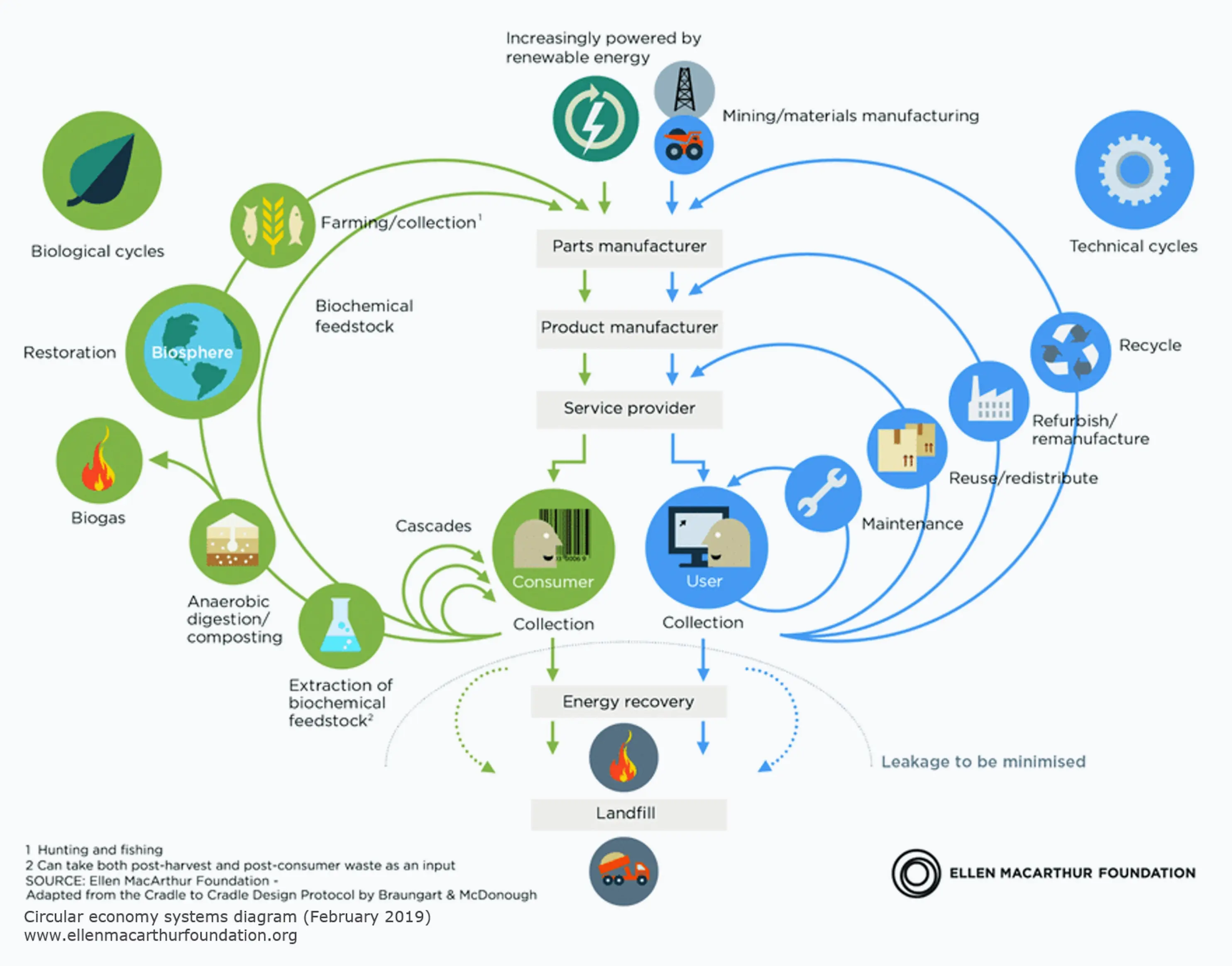

A look at this diagram will help you understand. Here we see the symbolic representation of two raw material loops – one in green, the other in blue. This diagram is based on the Ellen McArthur Foundation’s Circular Economy model. The colour green denotes the biological cycle of organic raw materials, whereas blue symbolises the technical cycle of materials such as metal or plastic from production to recycling.

The circular economy is a model of production and consumption in which existing materials and products are shared, leased, reused, repaired, refurbished and recycled for as long as possible. This prolongs the life cycle of the products. In practice, it means that waste is reduced to a minimum.

In our field of work, when we talk about product concepts for a true circular economy, we are primarily referring to the outermost blue cycle called “recycling”.

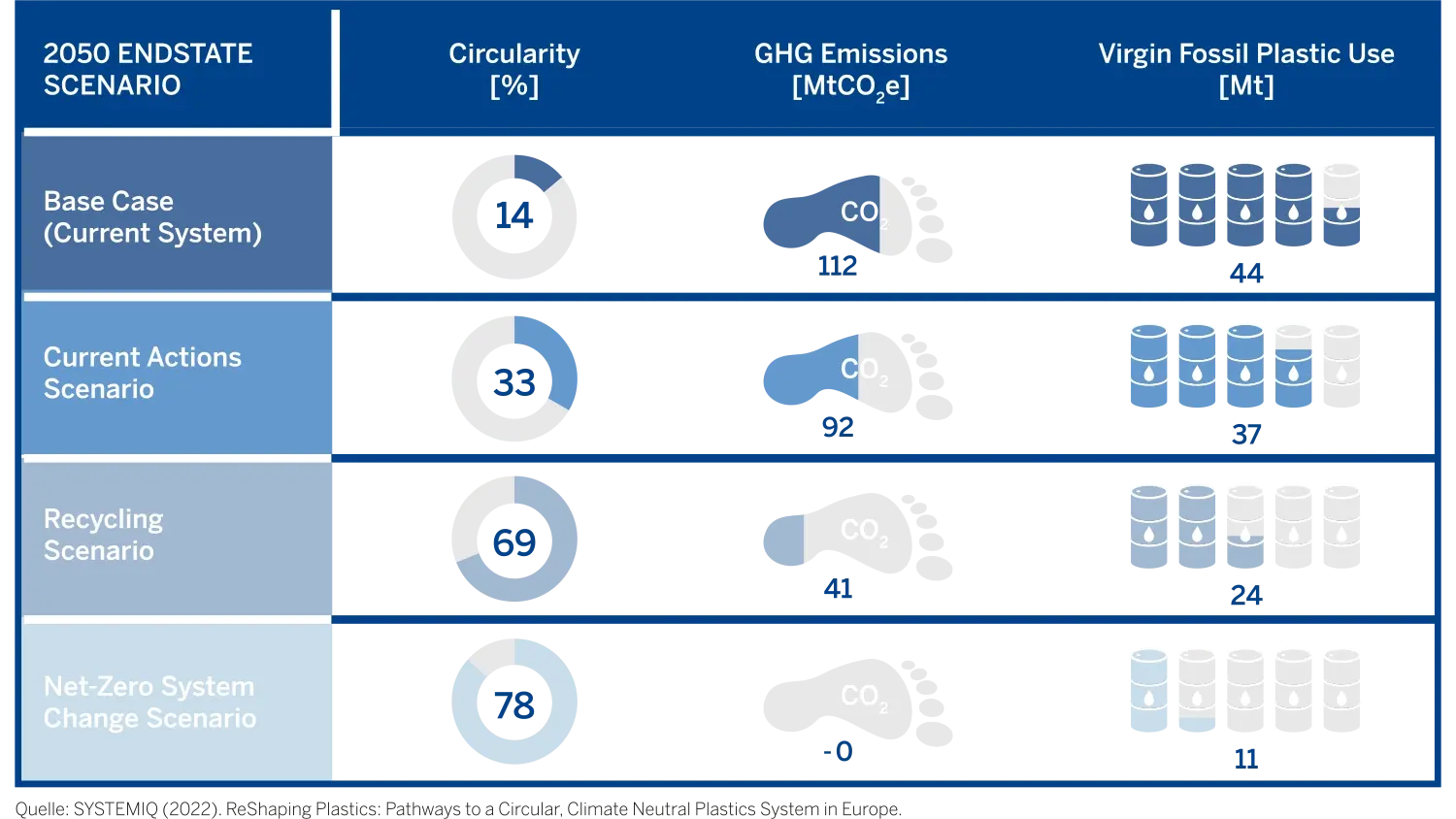

Studies show: The circular economy conserves resources and protects the climate.

BUT: We are still not doing enough!

The most important findings of the study:

- The circular economy can significantly reduce GHG emissions and waste generation.

- Our actions over the next 3-5 years will determine whether we can become GHG-neutral by 2050.

- All the measures implemented and announced by industry to date are far from sufficient to achieve the climate targets.

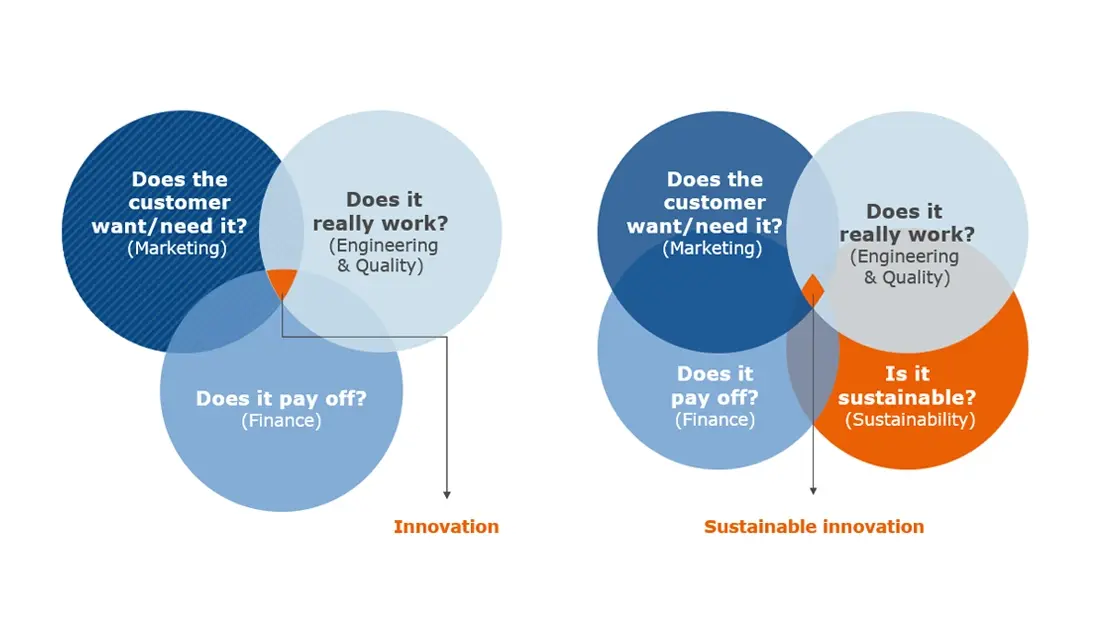

Sustainability needs a place at the decision-making table;

Climate protection and resource conservation must be a criterion.

Close cycles together now,

conserve resources and protect our climate!

We achieve resource conservation and climate protection through:

- a holistic, systemic perspective.

- thinking in terms of material flows from material to product to material.

- taking account of the material as a variable as early as the development stage.

- Awareness that climate protection and resource conservation are core requirements.

Together

We are partners of the following networks:

Contact

Do you want to participate? Let's talk about it!

On-site

Our sales representatives can come straight to your premises. Make an appointment now.

+49 4442 982-0

Monday through Thursday: 8:00 – 17:00 p.m.

Friday: 8:00 – 15:30 p.m.

By e-mail

Twenty-four hours a day. We will get back to you as soon as possible.