Lightweight construction and ORGANIC SHEETS

Holder SAM

CO2e-Footprint:

-44%

Technology:

TSG + PP GF30 (PIR)

Long-standing experience of PIR, PCR and end-of-life automotive material in series applications.

Metal replacement for less weight and CO₂e savings of up to 87%.

Less weight and CO₂e through technological know-how.

In-house compounding and laboratory expertise ensure quality.

As an automotive specialist, we combine sustainability and performance. Our innovative strength is based on sound expertise and state-of-the-art infrastructure. This allows us to set new standards for circular automotive solutions:

White paper: From old car to new car.

How you can already meet the planned ELV requirements with recycled materials.

What you can expect in the white paper:

What sets us apart from others:

Complete materials expertise under one roof. From the laboratory with the highest quality standards to in-house compounding for material preparation and innovative production technologies, we reduce resource consumption across the board. Years before the planned ELV, we are already supplying the sustainable automotive solutions of tomorrow in series production.

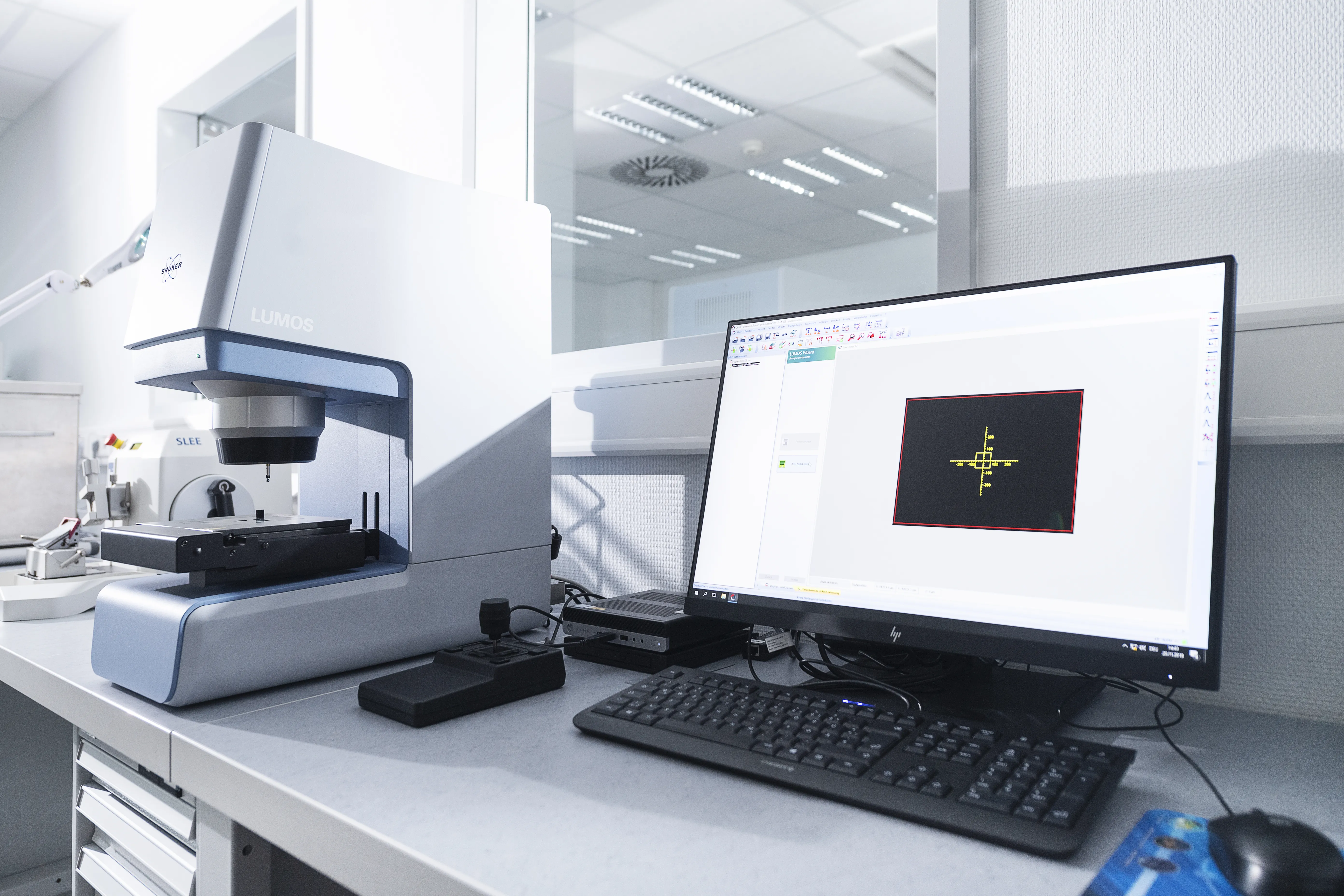

Our in-house test laboratory is a unique selling point in the industry and the heart of our circular performance. We use state-of-the-art testing methods to precisely characterize recycled materials and create validated simulation data for the highest development quality. From leak tests to cleanliness analyses, our laboratory guarantees the highest quality and functionality.

We combine in-depth knowledge of materials with state-of-the-art manufacturing processes. From classic injection molding and innovative foaming technologies to thermoforming and organic sheet processing - our expertise lies in the perfect match between material and manufacturing process. This combination enables us to provide optimal solutions for demanding automotive applications.

Our own compounding facility with an annual capacity of 10,000 tons is the foundation for a genuine circular economy. With in-house material development and the legally compliant use of recyclates, we create tailor-made solutions.

Different recyclate sources and in-house expertise eliminate fluctuations in quality and ensure consistent delivery capability.

While the industry reacts to upcoming sustainability regulations, we are already one step ahead. With scientifically validated material qualification and established recyclate supply chains, we are already creating compliance for tomorrow's regulations. Our expertise in the legally compliant implementation of recycled materials makes us a strategic partner for future-oriented companies.

Whether using recycled materials, reducing weight or saving materials – our experts support you with experience and ideas that boost performance.

Talk to us – together we will find the right solution.