We secure, GUIDE and protect

YOUR E/E comonents sustainabily.

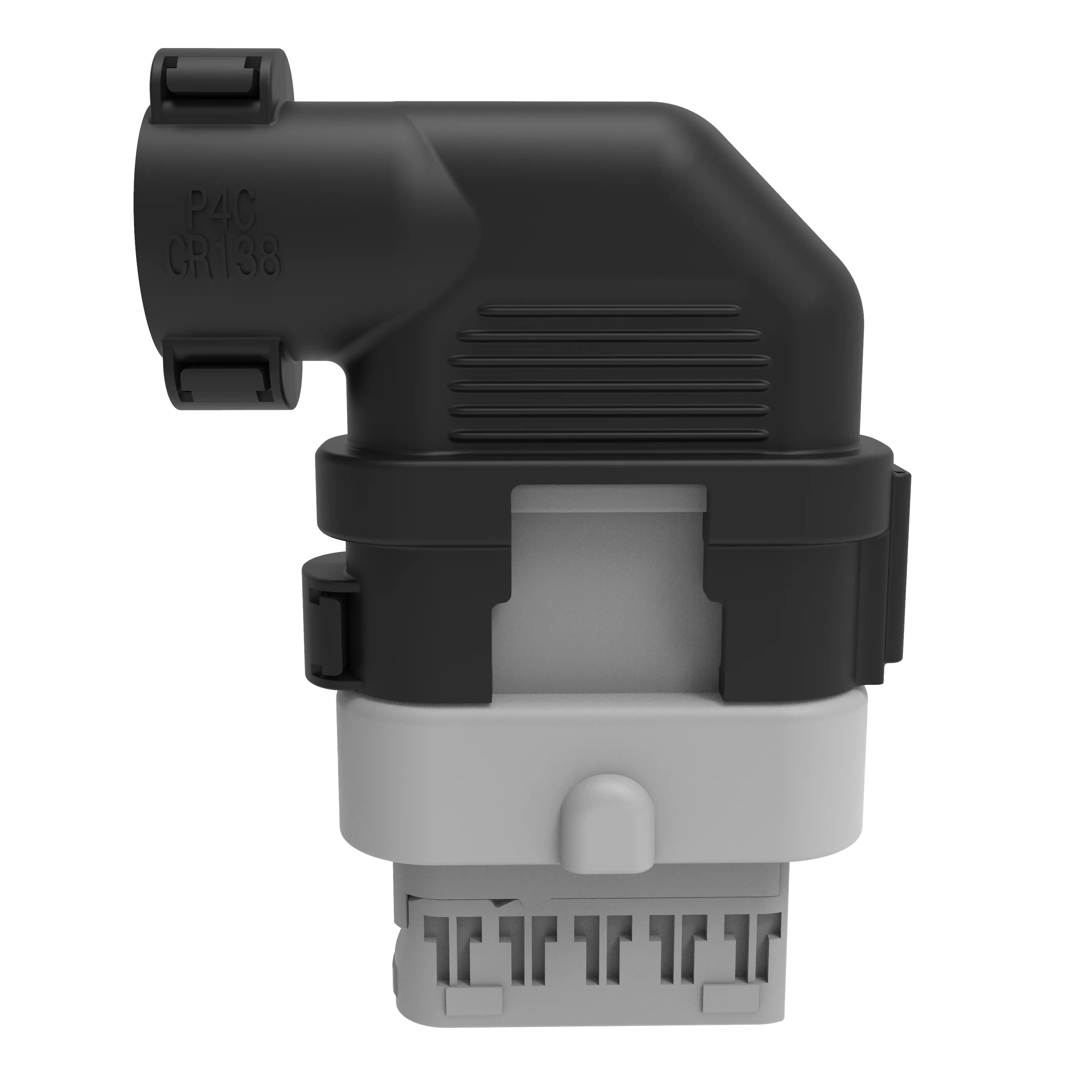

Protectors4Connectors - The dynamically growing K-TECH® program for quickly available protection and fastening systems.

Reduce CO2 with less material and modern technologies.

Short

Development times.

All from one

Hand.

According to requirements

and innovative.

IATF 16949 and

DIN EN ISO 9001 certified.

As a reliable partner to the automotive and industrial sectors, we develop tailor-made injection-moulded parts - from project support to series production. Even with complex requirements, we work together to find the optimum, economical and resource-saving solution. With comprehensive in-house expertise, we implement your projects efficiently and precisely.

Reliable, collaborative, one step ahead.

We are already working on the future topics of the automotive industry today.

From e-bike components to solar products, we are shaping the industry of tomorrow.

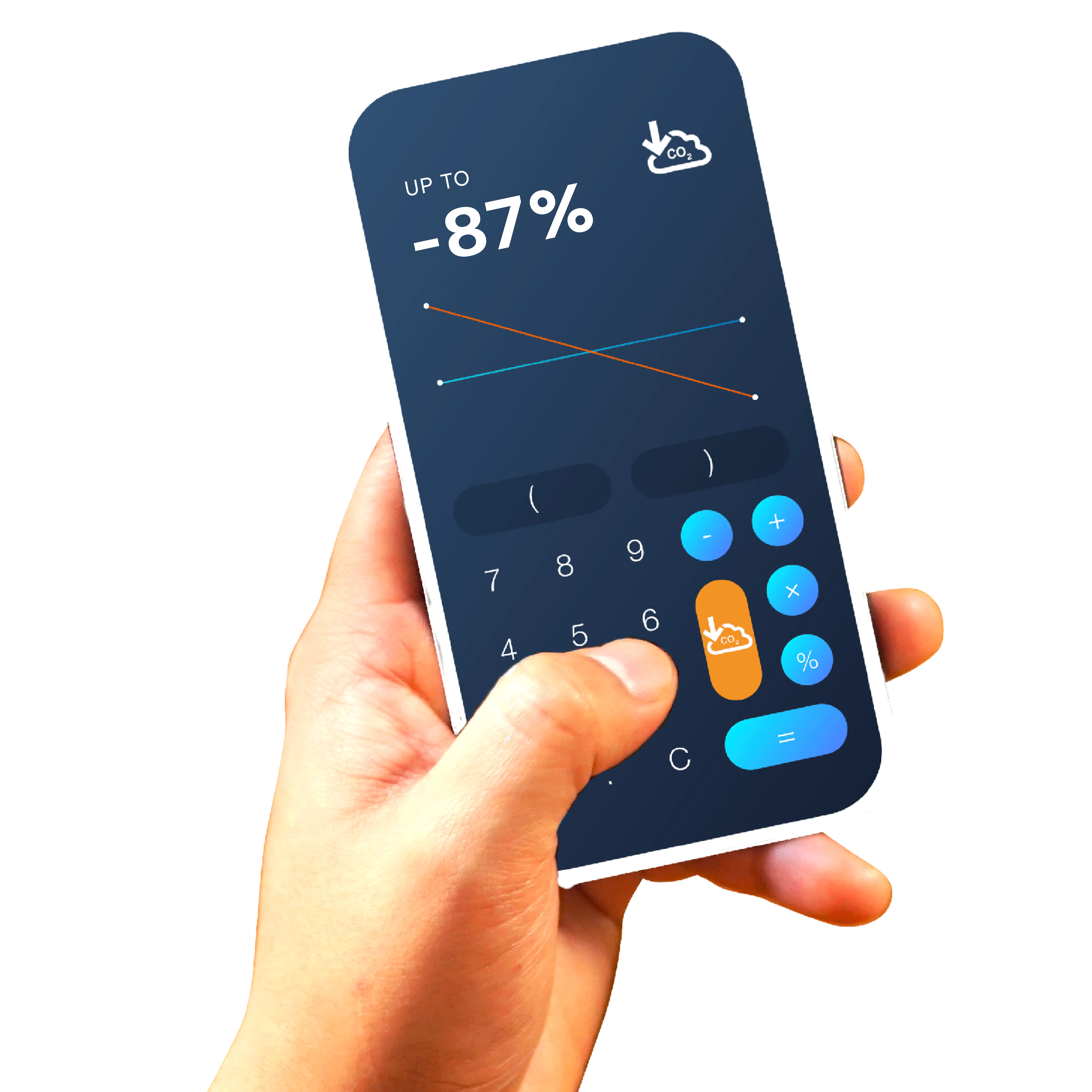

Up to 87% less CO2 emissions while maintaining the same quality - thanks to the use of recycled material. Calculate the CO2 footprint of your Protectors4Connector article in 3 steps.

Protectors4Connectors - The dynamically growing K-TECH® program for quickly available protection and fastening systems.

Three Pöppelmann apprentices gained unique skills and cultural insights abroad through Erasmus+ – from Portugal’s charm to Hungary’s innovative workplace.

At K 2025, Pöppelmann showcases PERFORMANCE. NOW. – market-ready solutions setting new standards in speed, quality, sustainability, and engineering excellence.

The EU Commission aims to significantly increase the proportion of recycled plastics in vehicles with the planned End-of-Life Vehicles Regulation (ELV). We have been working on this topic for a long time and can already provide suitable answers today.

The family-owned company Pöppelmann with its 2,500 employees worldwide,

with its 4 divisions KAPSTO®, K-TECH®, FAMAC® and TEKU® for its

customers at 6 production sites.