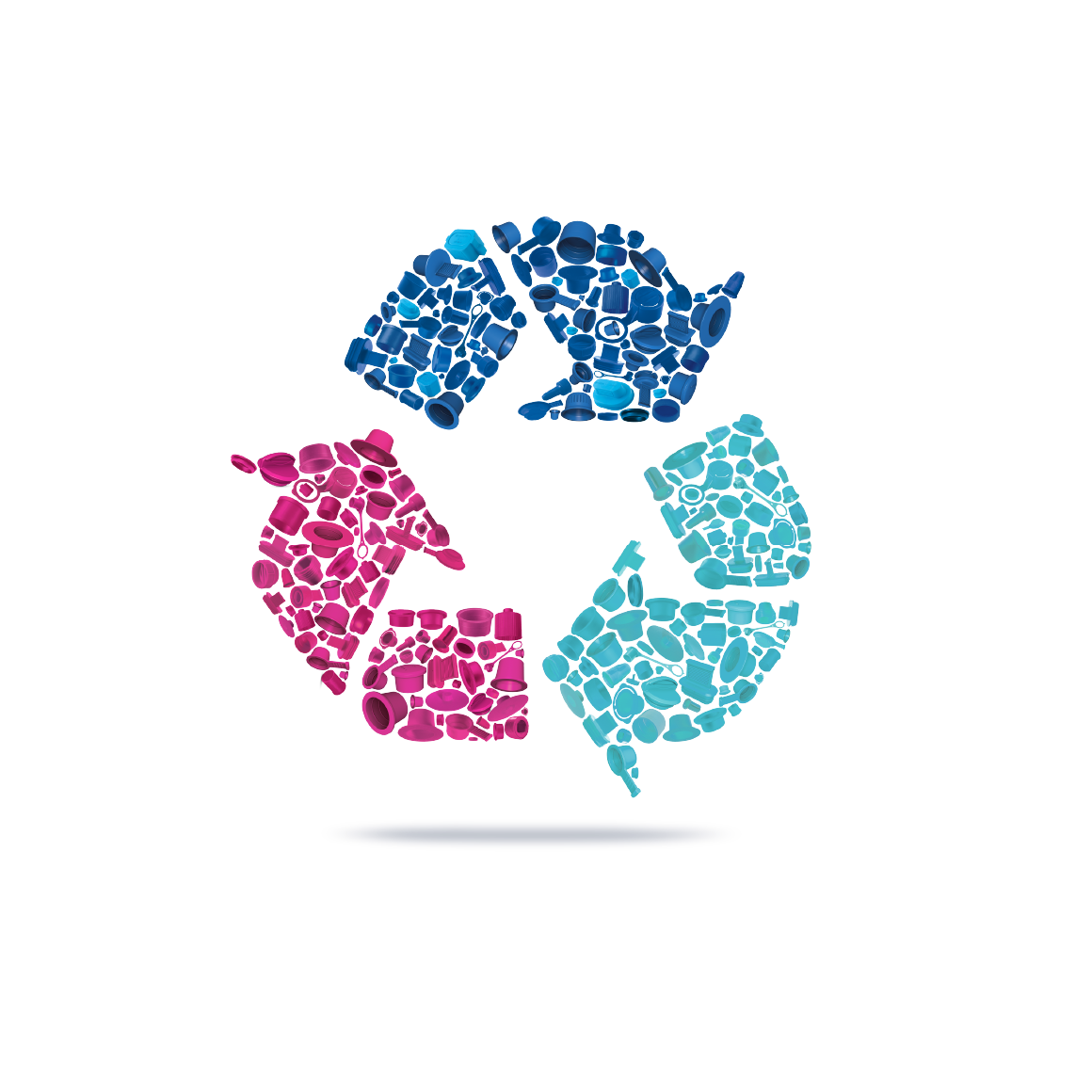

Recyclate is not just recyclate

To understand the background to the circular economy, a distinction must be made between post-industrial recyclate and post-consumer recyclate:

Post-industrial recyclates (PIR) are recycled production waste, for example waste and material from products that have not yet been used as a product.

Post-consumer recyclate (PCR), on the other hand, is obtained by recycling the material of a used product after it has been used and disposed of, for example in the yellow bag.

A true cycle can only be created with recyclates made from post-consumer waste, because only the use of PCR reduces the amount of fossil raw materials that need to be extracted.