In particular, the technical center prepares and implements the maturation of products for series production. In addition, cross-divisional knowledge is bundled in order to drive forward technological development at Pöppelmann and ensure the future viability of the company. In particular, networking between business units, central departments and external partners is being strengthened - both nationally and internationally - while technical standards are being further developed.

Comprehensive resources are available on site for component development, from concept creation to series production of customer projects, as well as in the area of material development:

-

Laboratory compounder: production and testing of formulations made from recycled plastic

-

Tools for test specimens: creation of compact and protected material samples.

-

Injection molding machines: production for the validation of recipes and series articles

-

Material analysis laboratory: carrying out detailed material analyses

-

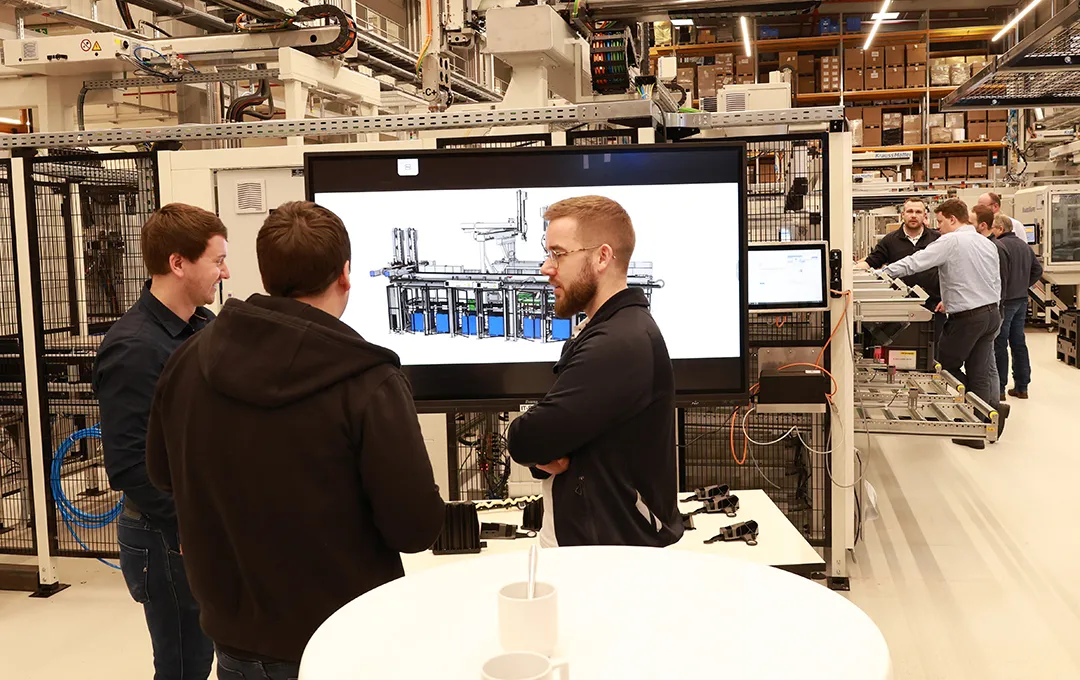

Automation equipment: validation of series automation solutions

These resources enable rapid adaptation and further development of plastic formulations. The material data obtained flows directly into our simulation tools and enables us to make well-founded statements on component performance at an early stage. After successful validation, the transfer to series production takes place.