Individual: Customer-specific components and assemblies for laboratory use.

Maintaining the best of standards in cleanliness and hygiene is an important factor of success in the provision in the laboratory supplies and diagnostics sector.

Pöppelmann FAMAC® complies with all required standards. Providing a one-stop service, we satisfy a range of needs from development and toolmaking to clean-room production. Provided in accordance with GMP regulations, this comes with the appropriate documentation and is certified in accordance with DIN EN ISO 13485. We prioritise application security along with the highest of quality standards and technical sophistication in our plastic parts.

Microtiter Plate

96 well

Disposables

for molecular diagnostics

Filter plates

for molecular diagnostics

Reagentbox

for molecular diagnostics

Rack

for spin columns

Laboratory vessels, with and without lids,

for centrifugal use

Reaction vessels

Spin Column

with and without lid

Pöppelmann FAMAC® – your development partner for technical functional parts and modern packaging.

Our development capabilities are in line with the latest products, technologies and the highest market demands. Quality, perfect craftsmanship and high-tech production are the secrets behind our market-leading success.

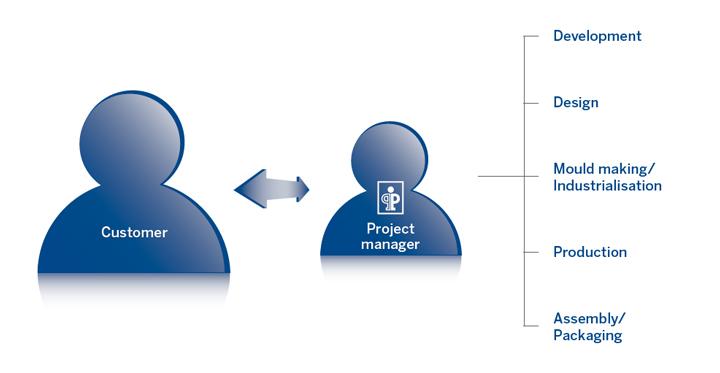

Customer-oriented and competent: With Pöppelmann as your development partner, you can rely on targeted product optimisation and safe process planning to manage quality and costs right from the start – because Pöppelmann FAMAC® is your one-stop shop, providing you with the plastics competency you need for your project. From design, fast development tools with virtual product development and optimisation (including CATIA V5, structural analyses (FEM), filling analyses, 3D simulations and DMU visualisations), and in-house in-house mould making to efficient high-end serial production. One project manager takes care of your needs at all times. – For a decisive competitive edge.

You might also be interested in the following topics:

Clean room production

Highest certified cleanliness

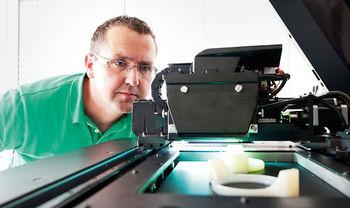

Rapid Prototyping

The faster route to series maturity

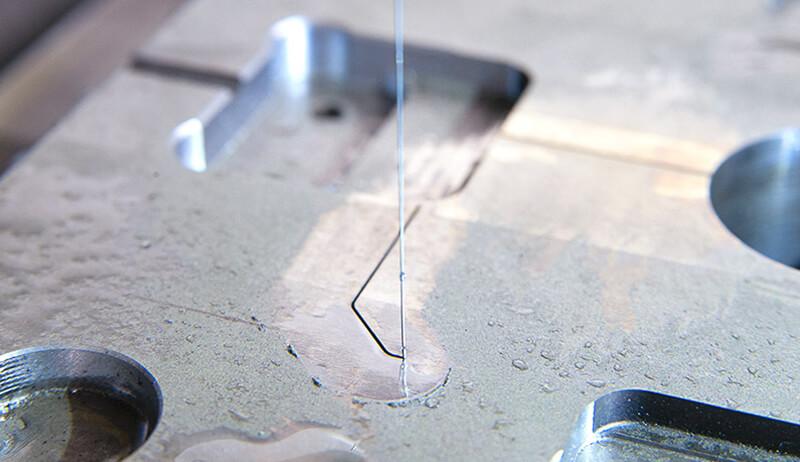

In-house tool making

Precision as the basis

Quality & Hygiene

For safety and reliability

Do you have any questions? The FAMAC® team will be happy to answer them.

On-site

Our sales representatives can come straight to your premises. Make an appointment now.

+49 4442 982-3900

Monday through Thursday: 8:00 – 17:00 p.m.

Friday: 8:00 – 15:30 p.m.

By e-mail

Twenty-four hours a day. We will get back to you as soon as possible.